Continuous Furnaces and Batch Furnaces

Shot Blasting Workhouses

This workshop is equipped with 6 shot blasting machines for cleaning and de-scaling heat-treated components. It consists of two main lines:

A : Gantry Shot Blasters

-

-

Large Overhead Shot Blaster (WMKD):

-

Maximum load per hanger: 2 tons

-

Maximum part dimensions: 20.3m x 8.1m

-

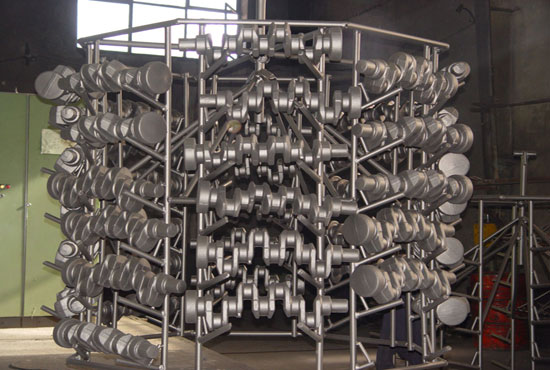

Hanger speed: 14 meters per minute This Swiss-made machine is primarily used for shot blasting front-end components such as axles, camshafts, crankshafts, and others with dimensions up to 20.3m x 10.3m x 8.2m. This machine is particularly suitable for long components. The machine has 3 hangers for shot blasting parts, each with a capacity of 2 tons. Parts are loaded onto the hangers, with a wide range of dimensions and weights up to 1600mm x 1900mm and 2 tons.

-

-

-

Small Overhead Shot Blaster

This machine, similar to the large overhead shot blaster, is used for shot blasting long components. It has 3 hangers with a capacity of 500 kg each and can accommodate parts up to 2200mm x 1600mm. Both the large and small overhead shot blasters are primarily used for shot blasting automotive front-end components such as crankshafts, camshafts, and axles, which due to their length, are susceptible to bending when shot blasted in a hanging position.

B. Rotary Conveyor Shot Blasters

-

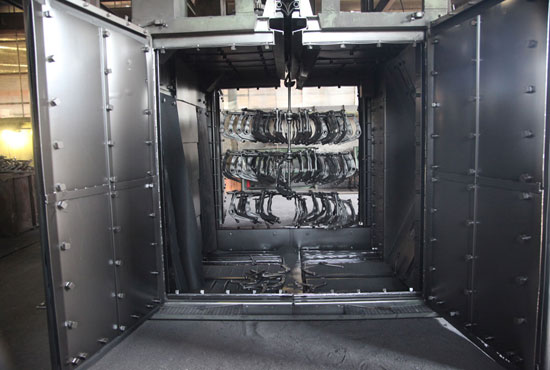

Large Shot Blaster 1 (WST): This Swiss-made machine is used for shot blasting and de-scaling various components with a weight capacity of 800 to 1200 kg per batch, depending on the part type and geometry. In this machine, parts are loaded into the shot blasting chamber by the machine’s loader and are rotated slowly by a conveyor while being shot blasted to ensure that all surfaces are cleaned and a smooth finish is achieved. The maximum load capacity of this machine is 2000 kg.

-

Large Shot Blasters 2, 3, and 26GN: These machines, manufactured in England, are used for shot blasting various heat-treated components, similar to the large shot blaster 1. They have a capacity of 800 to 1200 kg per batch. These machines also have internal conveyors for rotating the parts.

- Small Shot Blaster: 15GN