Heat Treatment Workshop :

This workshop is equipped with two lines of furnaces: continuous furnaces and batch furnaces. It performs various heat treatment processes, including normalizing, hardening, tempering, isothermal annealing, and full annealing.

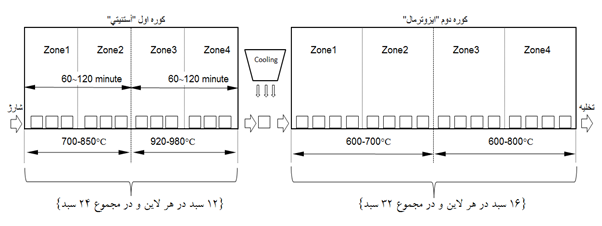

:Continuous Furnace (1) SAS This furnace, manufactured in England, operates on indirect gas firing. It is used for isothermal annealing of components weighing between 500 grams and 15 kilograms. The furnace has a pallet size of 980x1000mm and can process up to 16 tons of components per day. The furnace is equipped with a monitoring system to control holding time and temperature, and heat treatment records are stored in the system.

Continuous Furnace (2) ATBIN

This furnace was designed and installed by an Iranian company using Belgian technology. It operates on direct gas firing. Similar to Continuous Furnace 1, it is used for isothermal annealing of various gearbox components. It operates 24 hours a day with a pallet size of 850×850 millimeters, capable of processing between 100 grams and 15 kilograms of components per day. A significant feature of this furnace is its cooling system, which involves a closed-loop air circulation. After cooling, the air is recirculated and forced through the furnace to cool the components within a predetermined time. This process significantly improves the mechanical properties of the components. Like Continuous Furnace 1, this furnace is equipped with a monitoring system for automatic control of temperature, holding time, and recording heat treatment data.

Hardening and Tempering Line: SAS

This line, consisting of 6 batch furnaces, a charging machine, and an oil quenching tank, is designed and manufactured in England. All furnaces are electrically heated and used for hardening, tempering, normalizing, and full annealing heat treatments. These batch furnaces have a pallet size of 2100×1800 mm and can accommodate components weighing between 200 grams and 1.5 tons.

Quenching Unit: SAS Quenching unit

This unit is part of the hardening line system. After reaching the austenitizing temperature, components are transferred to the oil tank for hardening. Similar to the batch furnaces, this unit can handle components weighing between 800 kg and 1.5 tons, with a pallet size of 1800×2100 mm. In addition to a central chiller, the tank is equipped with another chiller for cooling and regulating the oil temperature, which is activated automatically based on the temperature set by the thermocouple. It’s worth noting that the tank’s operations, such as quenching, are performed automatically and precisely by pneumatic jacks and valves.

Charging Machine: SAS Charging machine

This machine is used for charging and discharging components into batch furnaces during heat treatment processes. It has a capacity of up to 1.5 tons.

Hardening Furnace: SAS Hardening furnace

Hardening furnaces are used to hold components at high temperatures between 830 and 920 degrees Celsius in the initial stage. These batch furnaces can accommodate components weighing approximately 800 kilograms to 1.5 tons.

Tempering Furnace: SAS Tempering furnace

These furnaces, commonly known as tempering furnaces, are used for the tempering process after hardening. They have a similar capacity to hardening furnaces and operate at temperatures between 450 and 680 degrees Celsius.

Overall, the entire hardening line, like the continuous furnaces, is monitored and controlled 24 hours a day by a control system. Temperatures, holding times, and heat treatment records are automatically recorded and stored by the system.

Atbin Furnace: A Detailed Overview

The Atbin furnace is designed and constructed for performing isothermal annealing heat treatment operations. It consists of several sections, each with specific functions. Below is a detailed description of these sections and their technical specifications.

Section 3: Isothermal Zone

This section consists of four temperature zones and is 17 meters long. Its purpose is to achieve a uniform transformation of austenite into ferrite and pearlite phases within the temperature range of 700-600°C. Temperature uniformity in this section is crucial for ensuring a homogeneous and uniform structure in the components. To achieve this, the furnace is equipped with an automatic temperature control system and a forced air circulation system with three vertical fans. The movement of components in this section is also automated using the walking beam system.

Furnace Doors and Automation

All three sections of the furnace have entrance and exit doors at both ends. These doors are controlled by the furnace’s PLC and can be opened and closed automatically as needed. The Atbin furnace operates continuously. The charging and discharging systems are also automated. Components are placed in standardized, weighed baskets and loaded into the furnace. At the end of the process, the baskets are automatically discharged onto pallets located at the end of the line.

Section 1: Heating Zone

This 12-meter-long section is divided into four temperature zones. Components are loaded into the furnace from the first zone, where the temperature is lowest due to proximity to the entrance door. The components move through the furnace on a walking beam system towards zones 2, 3, and 4. This movement is automated and controlled by the furnace’s PLC. As the components move forward, the temperature gradually increases. In zones 3 and 4, components reach the predetermined temperature for austenite transformation (960-900°C).

Section 2: Cooling Zone

This section is designed to cool components from the austenite temperature to 700-600°C. Cooling is achieved by blowing relatively warm air (140-200°C) into the chamber. Electric dampers allow for the adjustment of the cooling air temperature. The movement of pallets in the cooling chamber is controlled by hooks and chains. The cooling process is also programmable and controlled by the PLC.

Advantages of the Atbin Heat Treatment Furnace

- Efficient heating : The direct gas-fired heating system provides high thermal efficiency, allowing the furnace to reach temperatures up to 1000°C.

- Automated movement: The walking beam system, controlled by a PLC, ensures precise and automated component movement.

- Three separate heating zones: The furnace has distinct zones for austenitizing, cooling, and isothermal treatment.

- Programmable control: The PLC allows for precise control of the heating cycle and component movement.

- Uniform temperature: The forced air circulation system ensures uniform temperature distribution within the isothermal zone.

- Isolated cooling chamber :The cooling chamber is separate from the other zones, preventing heat transfer and ensuring precise cooling control.

- Damper control: Dampers allow for precise control of airflow and atmosphere within the furnace.

- Excellent insulation :The furnace is well-insulated with rock wool, minimizing heat loss.

- Durable construction :The furnace has a robust construction with a corrosion-resistant coating.